Introduction

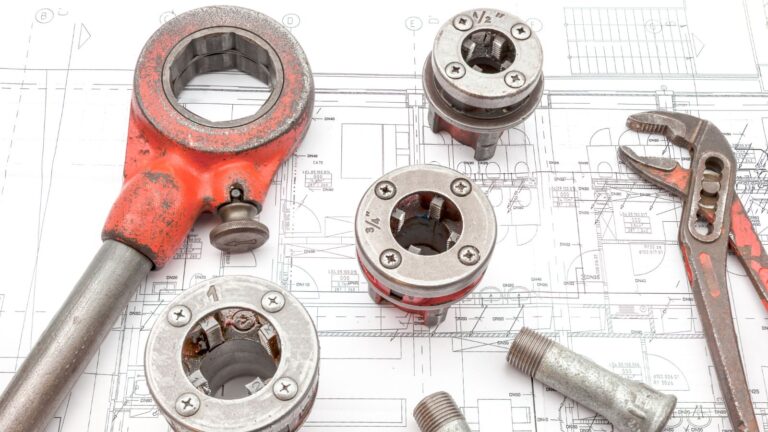

Welcome to the definitive guide for finding the perfect pipe threading machine tailored to your unique business needs. Pipe threading machines are essential tools for industries like plumbing, construction, and manufacturing, ensuring efficient and precise fabrication of pipes.

In this comprehensive guide, we’ll explore various types of pipe threaders, key factors to consider when choosing one for your business, top brands and models you can trust, as well as maintenance tips to prolong their lifespan.

Whether you are a seasoned professional or just starting in the industry, our ultimate guide is here to help simplify your decision-making process so that you can make an informed choice on which pipe threading machine will best serve your business’s requirements.

Key Takeaways

- Pipe threading machines come in different types, including manual and electric options, which cater to different project requirements and preferences.

- When choosing a pipe threading machine for your business needs, it’s essential to consider factors such as the pipe diameter and material, production volume, power source, ease of use and maintenance, and budget.

- Top brands like RIDGID, Rothenberger, Milwaukee offer reliable pipe threading machines suitable for various industries with different specifications that can simplify operations while ensuring accuracy.

- Purchasing from industrial machinery suppliers or online retailers specializing in plumbing tools and equipment is recommended to purchase high-quality pipe-threading machines from dependable manufacturers like those mentioned in this guide.

Understanding Pipe Threading Machines

Pipe threading machines come in different types, and are essential for businesses involved in pipe fabrication, plumbing, construction machinery or manufacturing equipment.

Types Of Pipe Threading Machines

There are several types of pipe threading machines available in the market, each designed to cater to different project requirements and preferences. The two main categories include manual pipe threaders and electric pipe threaders.

Manual pipe threaders are ideal for those who prefer a hands-on approach, as they require physical effort and can handle smaller projects with ease.

On the other hand, electric pipe threading machines offer an efficient and time-saving solution for businesses handling larger volumes or working with various materials such as steel pipes.

These machines come equipped with powerful motors that automate the entire threading process, making them suitable for heavy-duty tasks in construction sites or manufacturing facilities.

Electric threading machines may range from compact handheld models perfect for off-grid living situations to industrial-grade machinery designed for long-term use in professional settings.

Importance Of Pipe Threading Machines For Businesses

Pipe threading machines are essential tools for businesses involved in pipe fabrication, industrial pipe threading, plumbing, and construction projects. These machines enable workers to cut precise threads on pipes of different materials and sizes with ease.

Without them, achieving accurate thread cuts would be a time-consuming task that requires significant effort and skill. Furthermore, using these machines can increase productivity by allowing workers to complete tasks faster and more efficiently than they would using manual methods.

Moreover, choosing the right pipe threading machine is crucial as it impacts your project’s success directly. For instance, if you require heavy-duty equipment for rugged worksites or high-volume production areas, investing in a powerful electric threading machine or industrial-grade machinery such as RIDGID or Rothenberger brand can ensure efficient operations without compromising quality.

Factors To Consider When Choosing A Pipe Threading Machine

When choosing a pipe threading machine, it’s crucial to consider factors such as the pipe diameter and material, production volume, power source, ease of use and maintenance, and budget.

Pipe Diameter And Material

The diameter of the pipe and the material it’s made of are crucial factors to consider when choosing a pipe threading machine. The size of the pipe determines the type of die head needed for threading, which can affect your overall production efficiency.

Different materials also require different levels of thread accuracy and strength. For example, thicker pipes made from metals like stainless steel or iron may require heavy-duty machines with more power than those used for thinner plastic or copper pipes.

Production Volume

One of the most important factors to consider when choosing a pipe threading machine for your business needs is production volume. If you’re working on small projects with low-volume output, then a compact handheld threading machine may suffice.

Consider the amount of pipes that need to be threaded per day and how quickly they must be done. Choosing a machine that can handle your desired level of output is critical to ensuring efficiency and productivity within your business operations.

Power Source

One of the important factors to consider when choosing a pipe threading machine is the power source. There are typically two types of power sources for pipe threaders: electric and manual.

Electric pipe threaders are powered by electricity, making them ideal for heavy-duty projects with high production volume, while also being able to handle larger diameter pipes.

On the other hand, manual pipe threaders require physical labor and are better suited for smaller projects or jobs off-grid where there may not be consistent access to electricity.

An example of an electric pipe threading machine brand mentioned in this article is RIDGID. They offer various models that cater to different sizes of piping systems and production volumes.

However, if you’re living off-grid, you may want to consider a compact handheld threading machine or one that runs on alternative energy sources like solar power or propane gas cylinders.

Ease Of Use And Maintenance

When choosing a pipe threading machine, ease of use and maintenance should be considered. Look for machines with simple controls that are easy to understand and operate. It’s also important to choose a machine that is easy to maintain, including regular cleaning and lubrication.

For example, some electric pipe threaders have automatic oiling systems for convenient lubrication and are designed with quick-release dies for fast size changes. Opting for a compact handheld threading machine can make it easier to move around work sites or off-grid locations while still getting quality output.

Budget

Another key factor to consider when choosing a pipe threading machine is your budget. Depending on the size and complexity of your project, you may need to invest in a higher-end machine with more advanced features.

However, it’s important not to overspend if you don’t need all the bells and whistles.

For example, Steel Dragon Tools offers a range of affordable yet durable pipe threaders designed specifically for heavy-duty industrial use. Meanwhile, Milwaukee has gained popularity among professionals for their compact handheld threading machines that are powerful enough to handle most applications at an accessible price point.

Top Brands And Models Of Pipe Threading Machines

Discover the top brands and models of pipe threading machines, including RIDGID, Rothenberger, Milwaukee, and more, to ensure you choose the best option for your business needs.

RIDGID

RIDGID is a well-known brand in the world of pipe threading machines, and for good reason. They offer a wide range of high-quality pipe threaders that are durable and reliable.

One popular option is the RIDGID 535A Automatic Pipe Threading Machine, which can thread pipes up to 2 inches in diameter with ease.

Another great product from RIDGID is their manual pipe threader set. This compact handheld tool is perfect for smaller projects or off-grid locations where electricity may not be readily available.

With its easy-to-use design and interchangeable die heads, you can quickly create accurate threads on pipes up to 1 inch in diameter.

Rothenberger

Rothenberger is a well-known brand in the pipe threading machine industry. They offer a range of products from electric to manual threaders and provide solutions for industrial, plumbing, and building applications.

Their compact handheld threading machines are perfect for off grid living as they are easy to transport and operate without needing an external power source. Rothenberger also offers various accessories such as die heads, cutting oil, pipe cutters, and reamers that can be used with their equipment.

Milwaukee

Milwaukee is another reliable brand of pipe threading machines that businesses can consider. Their electric pipe threaders are known for their speed and efficiency, making them a great option for high-volume production.

Milwaukee offers both corded and cordless models to suit different work environments.

In addition to electric pipe threaders, Milwaukee also offers other plumbing tools such as power drills and compact handheld threading machines. These can be useful for off-grid living where access to electricity may be limited or inconsistent.

Steel Dragon Tools

Steel Dragon Tools is a reliable brand in the world of pipe threading machines. They offer a wide range of products, including manual threaders, electric pipe threaders, and bolt threading machines that are perfect for businesses with varying needs.

Their tools are designed to be durable and long-lasting, making them ideal for off-grid living where repairs or replacements may not be as readily available.

One standout product from Steel Dragon Tools is their compact handheld threading machine which is easy to use and transport when working remotely. Another great offering is the bolt threading equipment which can handle heavy-duty jobs with precision and accuracy.

Other Reliable Brands

Apart from the top brands and models mentioned in this guide, there are other reliable brands worth considering when looking for a pipe threading machine. For instance, the Rex Industries Company produces high-quality electric pipe threaders that are durable and efficient, with advanced features such as adjustable die heads for easy threading of different sizes.

The Apollo Machinery also offers various types of manual and electric pipe threaders that are ideal for small scale projects or home use.

Another brand worth mentioning is the Grizzly Industrial, which specializes in heavy-duty equipment for industrial applications. Their collection includes powerful pipe cutting machines, bolt threading machines, rod threading machines, among others.

Overall, choosing a reliable brand when shopping for a pipe threading machine is crucial to achieving success on any project.

Maintenance, Safety, And Training Tips For Pipe Threading Machines

To ensure the longevity and safety of your pipe threading machine, it is important to follow proper maintenance and training guidelines. In this section, we will provide tips on regular cleaning and lubrication, proper usage and handling, safety precautions, operator training, and certification.

Regular Cleaning And Lubrication

It is essential to keep your pipe threading machine clean and well-maintained to ensure smooth operation and avoid any damage. Regular cleaning and lubrication are crucial for the longevity of your equipment, especially if you plan on using it off-grid.

Before starting any maintenance or cleaning procedure, make sure the machine is turned off and unplugged. Use a soft-bristled brush or air compressor to remove any debris or dirt from the machine’s surface.

Wipe down all parts with a clean cloth, paying close attention to areas that may be prone to accumulating dust or grime. Apply a light coat of oil to movable parts such as gears, levers, bearings, and screws for lubrication, which will help reduce friction between moving metal parts resulting in less wear over time.

Proper Usage And Handling

Using and handling a pipe threading machine correctly is crucial to avoiding accidents and prolonging its lifespan. Before usage, familiarize yourself with the machine’s user manual, safety guidelines, and any training requirements.

Make sure that the pipe threading machine is on a flat surface before operating it. Use clamps or vices to secure the workpiece to prevent slippage during threading. Never force the threader or exceed its capacity limits as this can damage both the tool and tubing.

Regularly inspect your equipment for signs of wear or damage, including broken parts or frayed cords.

Safety Precautions And Guidelines

Before using a pipe threading machine, it is important to follow safety precautions and guidelines to prevent accidents or injuries. Always wear appropriate protective gear such as safety glasses and gloves.

It’s also crucial to secure the machine firmly on a stable surface before use. Avoid wearing loose clothing or jewelry that could get caught in the machine during operation.

Additionally, avoid putting your hand near moving parts while the machine is running.

Operator Training And Certification

It is important to ensure that the operator of the pipe threading machine is well trained and equipped with the necessary skills to handle the equipment safely and efficiently.

This includes knowledge of how to set up, operate, clean, and maintain the machinery properly.

Furthermore, proper operator training can also prevent accidents and injuries in the workplace. The Occupational Safety and Health Administration (OSHA) requires all operators of heavy-duty machinery to receive adequate training before operating any equipment on a job site.

Where To Purchase And Conclusion

In conclusion, choosing the perfect pipe threading machine for your business needs can be a daunting task. However, by understanding the types of machines available and considering factors such as production volume and budget, you can make an informed decision.

Remember to prioritize safety and maintenance when operating these powerful tools. To purchase a reliable pipe threading machine from trusted brands like RIDGID or Rothenberger, consider visiting industrial machinery suppliers or online retailers specializing in plumbing tools and equipment.

FAQs:

1. What factors should I consider when choosing a pipe threading machine for my business needs?

When selecting a pipe threading machine, it is important to consider the size of pipes you will be working with, the frequency and volume of usage, as well as your budget and space requirements. You may also want to evaluate performance features such as speed, accuracy and ease-of-use.

2. How do I know which type of thread cutting method is best for my operations?

There are several types of thread cutting methods available including manual dies, automatic dies and CNC-controlled systems. Determining which method is best for your operations requires an understanding of your specific needs along with evaluation of each system’s pros and cons.

3. Can I purchase used or refurbished pipe threading machines instead of new ones?

Yes! Used or refurbished machines can often provide cost savings while still improving overall production efficiency if properly inspected before purchasing by experienced professionals who specialize in refurbishing like-new condition equipment at affordable prices – just make sure you purchase from reputable source that has good reviews & offers warranty on products sold.

4. How do I maintain my pipe threading machine so it stays running smoothly over time?

Regular maintenance tasks include keeping the work area clean & free from debris or dust particles that could clog up machinery components; adjusting lubrication cycle times based upon manufacturer recommendations in order to prevent wear-and-tear on parts subject to constant friction; replacing worn-out parts on schedule basis recommended by manufacturer guidelines are all essential steps towards maintaining healthy machinery for pipeline fabrication jobs no matter their duration or complexity level