Have you ever wondered about the intricate details found in handmade jewelry pieces? These stunning designs often emerge from a process known as wax casting. This comprehensive guide will illuminate every step of the journey, from sourcing quality wax casting supplies to mastering craftsmanship techniques.

Let’s embark on a captivating exploration into the world of jewelry making and discover how you can create your own beautiful pieces!

Key Takeaways

- Wax casting is a jewelry – making process that allows for the creation of intricate and highly detailed designs using wax models.

- Essential supplies for wax casting include carving wax blocks and sheets, wax carving tools, casting flasks and investment materials, as well as a kiln or torch for melting the wax.

- Additional tools and equipment that can enhance the wax casting process include casting machines and centrifuges, vacuum chambers and pumps, wax injectors and pens, burnout ovens or kilns. These tools offer greater precision, efficiency, and control in creating unique jewelry pieces.

- Investing in high – quality supplies from reliable suppliers ensures consistent results and saves time and effort in refining finished pieces.

What is Wax Casting?

Wax casting is a jewelry-making process that involves creating intricate designs using wax models, which are then transformed into metal through a casting process.

The process of creating jewelry using wax models

Creating jewelry through the use of wax models is an artistic process rich in history and still widely used today. Known as lost wax casting, this technique allows craftsmen to design intricate pieces with a high level of detail.

They start by meticulously carving out their desired shape from a block of special carving wax. This carved model serves as the original piece from which all subsequent copies will be made. Once satisfied with their design, craftspeople then construct a shell or “investment” around it using plaster-like investment powder.

Upon heating, the embedded wax model melts and evaporates – hence the term “lost wax.” This leaves behind a perfect mold ready for molten metal pouring. The end result is a durable yet beautifully detailed piece that reflects both skill and creativity synonymous with artisanal jewelry making.

How wax casting allows for intricate and detailed designs

Wax casting is a jewelry making technique that allows for the creation of intricate and highly detailed designs. By using wax models, jewelers can create complex shapes and patterns before casting them in metal.

The beauty of wax casting lies in its ability to capture even the most delicate details, such as filigree work or textured surfaces. This technique opens up a world of possibilities for creating unique and personalized jewelry pieces that are truly one-of-a-kind.

Whether you’re a beginner or an experienced jeweler, exploring the art of wax casting will allow you to unleash your creativity and bring your design visions to life.

Essential Wax Casting Supplies

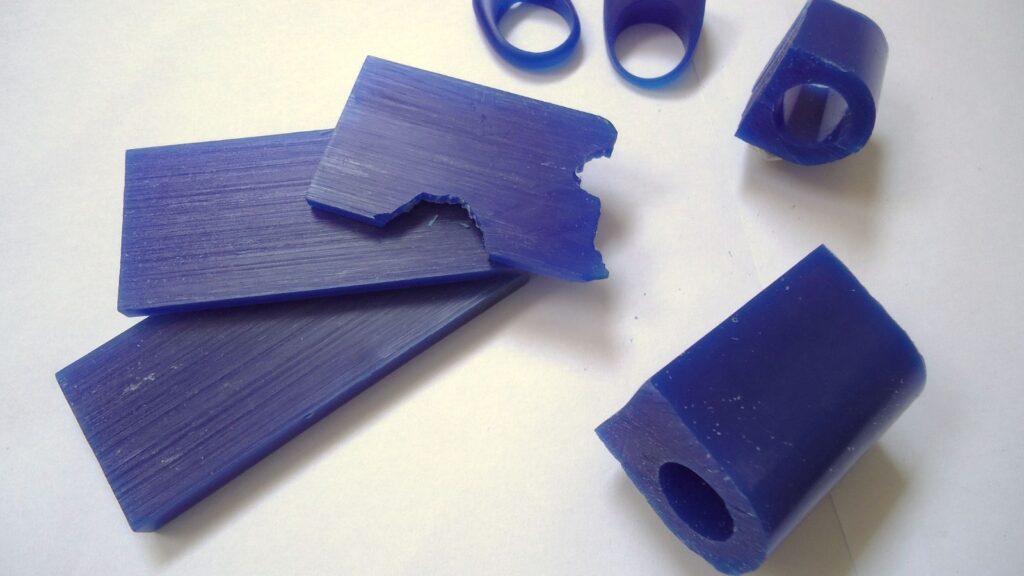

Wax for jewellery carving. Lost wax process. Photo : Mauro Cateb, Brazilian jeweler.

To get started with wax casting, you’ll need essential supplies like carving wax blocks and sheets, wax carving tools, casting flasks and investment materials, as well as a kiln or torch for melting the wax.

Carving wax blocks and sheets

Carving wax blocks and sheets are essential supplies for anyone interested in off-grid jewelry making. These waxes come in various hardness levels, allowing jewelers to choose the one that best suits their carving techniques and designs.

Harder waxes hold intricate details better, while softer waxes are easier to manipulate. With the right tools, such as wax carving knives or files, these blocks and sheets can be transformed into beautiful jewelry molds.

Whether you’re a beginner or an experienced jeweler, having a variety of carving wax options will give you the versatility to create unique pieces that reflect your artistic vision.

Wax carving tools

Wax carving tools are essential for creating intricate designs and fine details in wax models for jewelry making. These tools come in various shapes, sizes, and materials to suit different carving techniques and personal preferences.

Some common types of wax carving tools include carving knives, spatulas, files, picks, and melting spoons. With these tools at your disposal, you can easily shape the wax into desired forms and textures.

Whether you’re a beginner or an experienced jewelry maker, investing in high-quality wax carving tools will ensure precise results and make your creative process much smoother.

Casting flasks and investment materials

Casting flasks and investment materials are essential for successful wax casting in jewelry making. Casting flasks, also known as molds, are used to hold the wax models during the casting process.

They come in various shapes and sizes to accommodate different jewelry designs. Investment materials, such as plaster or ceramic-based compounds, are used to create a mold around the wax model inside the flask.

These investment materials play a crucial role in creating high-quality castings by providing support and stability during the pouring of molten metal. They also help ensure that there is no distortion or shrinkage during the cooling process.

Choosing the right investment material is important based on factors like type of metal being casted and desired surface finish.

Investment powders can be mixed with water to create a slurry that is poured into the flask around the wax model. Once set, it forms a hard mold that can withstand high temperatures without cracking or breaking.

This allows for precise and detailed reproduction of intricate designs.

When investing in casting flasks and investment materials, it’s important to consider their quality and durability. Opting for high-quality products will result in better castings with fewer defects, saving you time and effort in refining finished pieces.

Reliable suppliers who specialize in jewelry making supplies should be chosen based on customer reviews and reputation within the industry.

To maintain these supplies properly, they should be stored safely when not in use to prevent damage or contamination. Regular cleaning of casting tools such as flasks is necessary after each use to prolong their lifespan.

Replenishing consumables like investment powder ensures consistent results with every batch of castings.

Kiln or torch for melting the wax

To melt the wax for your jewelry casting, you will need either a kiln or a torch. A kiln is an electric or gas-powered oven-like device that reaches high temperatures to heat and melt the wax.

It provides consistent and controlled heat, making it ideal for larger-scale production.

On the other hand, if you prefer a more portable option or have smaller projects, a torch can be used. This handheld tool allows you to apply direct flame onto the wax, melting it gradually.

Torch melting offers flexibility and precision as you can control the intensity of heat.

Regardless of which method you choose, ensure proper safety precautions when working with open flames or hot surfaces. Always wear protective gear and work in a well-ventilated area.

Additional Wax Casting Tools and Equipment

In addition to the essential supplies, there are several other tools and equipment that can enhance your wax casting process. These include casting machines and centrifuges for precise metal pouring, vacuum chambers and pumps for eliminating air bubbles in the mold, wax injectors and wax pens for intricate designs, and burnout ovens or kilns for properly melting the wax.

By investing in these additional tools, you can take your jewelry making skills to the next level. Explore different techniques with advanced equipment to create unique pieces that will stand out among others in the industry.

Discover how these tools can elevate your craft by reading more about them in this comprehensive guide!

Casting machines and centrifuges

Casting machines and centrifuges are essential tools for jewelry makers who want to take their wax casting skills to the next level. These machines provide a more efficient and precise way of creating jewelry pieces by automating the casting process.

With a casting machine, you can achieve consistent results every time, ensuring that your designs come out exactly as intended.

A centrifuge, on the other hand, is used to forcefully spin the molten metal into the desired shape within a mold. This spinning motion allows for better filling of intricate details and reduces porosity in the final piece.

Using a centrifuge ensures that you get clean, crisp castings with minimal defects.

Investing in a good quality casting machine and centrifuge can greatly enhance your wax casting capabilities. They allow you to experiment with different alloys and textures while maintaining accuracy and precision in your designs.

Whether you’re an experienced jeweler or just starting out with wax casting, these tools can help bring your creations to life with ease.

When choosing a casting machine or centrifuge, it’s important to consider factors such as power output, size capacity, and ease of use. Look for reputable suppliers that offer reliable brands known for their durability and performance.

Reading customer reviews can also give you insights into the pros and cons of different models before making your purchase.

Vacuum chambers and pumps

Vacuum chambers and pumps play a crucial role in the wax casting process for jewelry making. These tools are used to remove air bubbles from the investment material, ensuring that the final metal piece is free of defects and imperfections.

By creating a vacuum environment, the chambers and pumps allow the investment material to flow smoothly around the wax model, capturing all of its intricate details.

With a vacuum chamber and pump, jewelry makers can achieve high-quality castings with minimal effort. The chambers are typically made of sturdy materials like stainless steel or acrylic, ensuring durability and long-lasting use.

Meanwhile, the pumps create strong suction power to effectively remove any trapped air within the investment material.

Investing in quality vacuum chambers and pumps will significantly improve your wax casting results while also saving you time and money on potential rework. Ensure you choose equipment that meets your specific needs and consider factors such as size, capacity, and ease of use when making your selection.

Wax injectors and wax pens

Wax injectors and wax pens are essential tools for any jewelry maker or artisan practicing wax casting. These tools allow for precise and controlled wax injection into the casting molds, ensuring accurate replication of intricate designs.

Wax injectors use pressure to push molten wax into the mold cavity, while wax pens offer a more manual approach for precision detailing and touch-ups. Whether you’re creating delicate filigree work or adding fine details to your castings, these tools provide a level of control that is crucial in achieving high-quality results.

Invest in reliable and durable wax injectors and pens to enhance your craftsmanship and bring your creative visions to life with ease.

Burnout ovens and kilns

Burnout ovens and kilns are essential tools for wax casting in jewelry making. These devices are used to safely and effectively remove the wax from the mold before metal is poured in. The high temperatures inside these ovens and kilns burn away the wax, leaving behind a hollow cavity that will be filled with molten metal during the casting process.

Burnout ovens and kilns come in various sizes and designs, allowing for flexibility based on the size of the jewelry pieces being created. They play a crucial role in ensuring precise and accurate results in lost wax casting, making them indispensable for any serious jewelry maker.

Choosing the Right Wax Casting Supplies

When choosing the right wax casting supplies for your jewelry making projects, consider factors such as the specific design requirements, the quality and durability of the materials, and the reputation of the supplier.

Considerations for different jewelry designs

Different jewelry designs require different considerations when it comes to selecting the right wax casting supplies. For intricate and delicate designs, a softer carving wax may be preferred for easier manipulation.

On the other hand, if you’re working on larger and more robust pieces, a harder wax may provide better stability during the carving process. Additionally, consider the weight of the final metal piece – lighter designs may require less investment material and smaller flasks, while heavier pieces might need stronger molds and sturdier equipment.

By taking these factors into account, you can ensure that your chosen wax casting supplies are perfectly suited to bring your unique jewelry designs to life.

Quality and durability of the materials

Choosing high-quality and durable materials for wax casting supplies is crucial in creating beautiful and long-lasting jewelry pieces. Reliable suppliers offer a range of options that cater to different budgets and requirements.

It’s important to opt for high-quality wax blocks, sheets, and carving tools that are easy to work with and produce clean, precise cuts. Investing in sturdy casting flasks and reliable investment materials ensures successful mold creation and metal casting.

Additionally, selecting trusted brands for kilns or torches used to melt the wax guarantees efficient heating without compromising safety. When it comes to jewelry making, the quality of the materials directly affects the finished product’s appearance and durability over time.

Supplier reputation and customer reviews

When it comes to choosing the right wax casting supplies for your jewelry making projects, it’s important to consider the reputation of the supplier and read customer reviews. A reputable supplier will offer high-quality materials that are durable and reliable, ensuring that your wax casting process goes smoothly.

By reading customer reviews, you can get valuable insights into the quality and performance of different suppliers’ products, helping you make an informed decision. So before making any purchases, take the time to research and find a trusted supplier with positive reviews from satisfied customers.

Your jewelry making experience will be greatly enhanced by using supplies from a reputable source.

Maintaining and Caring for Wax Casting Supplies

Proper storage and regular maintenance are essential for keeping your wax casting supplies in top shape. From organizing your tools to cleaning carving tools, this section provides all the tips you need to ensure longevity and performance of your equipment.

Proper storage and organization

To ensure the longevity and usability of your wax casting supplies, proper storage and organization are essential. Keep your carving wax blocks and sheets in airtight containers or zip-lock bags to prevent them from drying out or becoming brittle.

Store your wax carving tools separately in a designated tool drawer or box to avoid damage or misplacement. It is also important to keep your casting flasks and investment materials in a clean, dry area away from moisture which can affect their effectiveness.

Regularly check and replenish consumables such as wax, investment powder, and other supplies to ensure you always have what you need on hand for your jewelry making projects. By maintaining an organized storage system for your wax casting supplies, you’ll save time and effort when it comes to creating beautiful pieces of jewelry through the lost wax casting process.

Cleaning and maintaining carving tools

Proper maintenance and care of your carving tools are essential for achieving high-quality results in wax casting. Regular cleaning not only ensures the longevity of your tools but also helps maintain their sharpness and accuracy.

After each use, make sure to remove any residual wax by wiping the tools with a soft cloth or tissue. Use a small brush or toothbrush to gently remove any stubborn wax residue from crevices or hard-to-reach areas.

It’s important to avoid using water as it can cause rusting and damage the tool’s handles. Additionally, periodically sharpening your carving tools will help ensure clean and precise cuts when working with wax models.

Replenishing wax, investment, and other consumables

To keep your wax casting process running smoothly, it’s important to regularly replenish your supplies of wax, investment powder, and other consumables. Wax is the primary material used in creating models for jewelry making through the lost wax casting method.

As you carve and shape your designs, it’s inevitable that you’ll use up your stock of carving wax blocks or sheets. Additionally, investment powder is needed to create the mold that will hold the melted metal during casting.

It’s crucial to have enough investment materials on hand to ensure successful casts every time. Other consumables may include brushes for applying investment powder, release agents for easy removal of finished pieces from molds, and protective equipment like gloves and masks.

Regular equipment maintenance and calibration

Regular equipment maintenance and calibration are crucial for the smooth operation of your wax casting supplies. By properly maintaining and calibrating your tools and equipment, you can ensure consistent and accurate results in your jewelry making process.

Regularly inspecting and cleaning your carving tools will help prevent build-up of wax residue that can affect their performance. It is also important to regularly replenish consumables such as wax and investment materials to avoid running out during a project.

Additionally, periodic equipment maintenance, such as checking kilns or torches for any issues, will help extend their lifespan and prevent unexpected breakdowns. Proper calibration ensures that your casting machines or centrifuges are operating at the correct settings for optimal results.

Conclusion

In conclusion, this comprehensive guide has provided you with all the essential information you need to get started with wax casting for jewelry making. From understanding the different types of wax and tools required, to exploring various casting techniques, we’ve covered it all.

By choosing the right supplies and following proper maintenance practices, you’ll be able to create stunning jewelry pieces using the timeless art of lost wax casting. So, go ahead and dive into this fascinating world of creativity and craftsmanship!

FAQs

1. What are the essential wax casting supplies needed for jewelry making?

The essential wax casting supplies for jewelry making include carving wax, injection waxes, sprue wax, investment material, a casting flask, a burnout kiln, and various tools like spatulas and files.

2. How do I choose the right type of wax for my jewelry casting project?

Choosing the right type of wax depends on factors such as your desired level of detail, complexity of the design, and intended final product. For intricate designs with fine details, you may opt for carving waxes or specialty waxes designed specifically for delicate work.

3. What is the purpose of an investment material in jewelry making?

An investment material is used to create a mold around the wax pattern before it goes into the kiln for burnout. It provides support during the casting process by holding its shape and preventing distortion.

4. Can I use a regular oven instead of a burnout kiln for wax casting?

It is generally not recommended to use a regular household oven instead of a dedicated burnout kiln for wax casting. Burnout kilns have precise temperature control settings necessary to ensure proper elimination of all traces of wax from within the mold without causing damage to delicate materials or compromising quality.